YCT-V11 vertical packing machine line

Product Application:

Machine description:

The whole production line includes:

1. Rack part

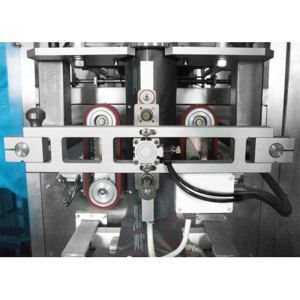

2. Vertical sealing part

3. Horizontal sealing part (cylinder standard) [high-speed machine] → servo

4. Film conveying part (film pulling part) servo motor drive

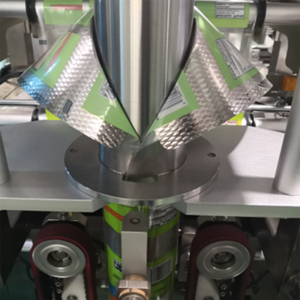

5. Film passing part (paper feeding part) film loading part

6. Bag maker part (former part) → core 1

7. Electrical part (electrical box) → core 2

Work process:

Working Principle:The core of the machine is PLC, which receives start and detect signals and output signals to start the automatic magnetic clutch, the electromagnetic valve,and the motor.

Operation process: put the product into the hopper—Automatically weighed—Automatically packed—Done.

Label specification:

①Applicable labels: sticker label, film, electronic supervision code, bar code.

②Applicable products: Products that are required to be labeled on flat, arc-shaped, round, concave, convex or other surfaces.

③Application industry: Widely used in cosmetics, food, toys, chemical, electronics, medicine and other industries.

④Application examples: shampoo flat bottle labeling, packaging box labeling, bottle cap, plastic shell labeling, etc.

Parameters:

Vertical packing machine parameters:

Bag making technical Parameters:

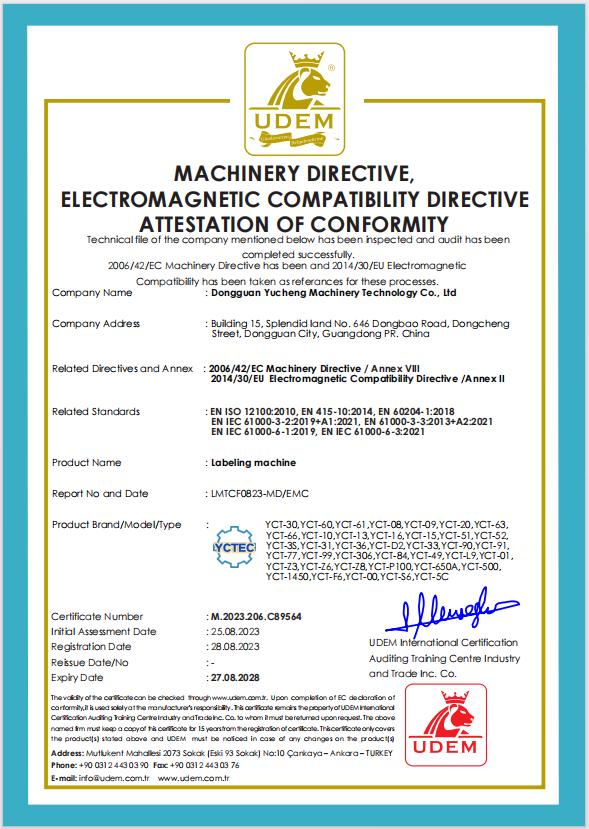

Certificate:

Video:

We have been deeply inivolved in the field of full

automatic packing equiments for more than 20 years.

We insist on making high-quality products, insisting on

making every product well, and providing customers

with better solutions, to bring safe, reliable and cost-

effective packaging machines and service to our

customers.

Yucheng Machinery

Yucheng Machinery