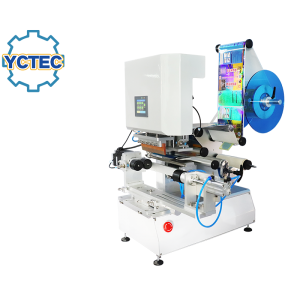

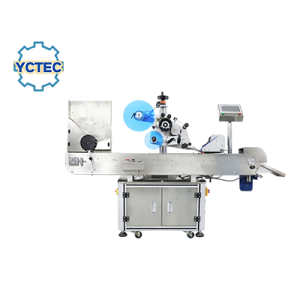

YCT-31 Full Automatic Card Labeling Machine

Product Application:

Machine description:

①YCT-31 automatic labeling of card products, apply to card, plastic bag, carton, paper and others slice products, such as thin plastic and thin chip labeling.

②It can achieve full coverage labeling, partial accurate labeling, vertical multi-label labeling and horizontal multi-label labeling, widely used in carton,plastic, electronic,card, OEM and printing materials industries.

③Optional functions:

1.configuration code printer or ink-jet printer, when labeling, print clear production batch number, production date, effective date and other information,coding and labeling will be carried out simultaneously, improve efficiency.

2.configuration printer,change printer contents at any time,realize the function of printing and labeling at the same time.

3.Automatic feeding function (combined with product consideration);

4.Automatic material collection function (combined with product consideration);

5.Increase labeling device;

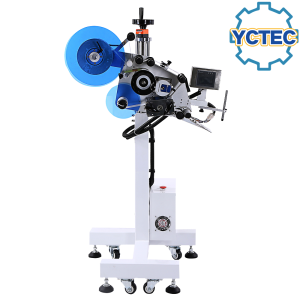

④The Adjust method is simple: 1.Adjust the height of the machine mechanism ,make the labeling knife edge higher 2mm than product height and at the same level. 2.Adjust the conveyor belt and labeling speed on the touch screen so that they want to match.3.Adjust the position of the sensor so that each label can be completely run out. 4.Adjust the position of the roller, make roller parallel to the conveyor belt and pressing on top of it.

⑤Machine floor space about 2.40 stere.

⑥Machine Support Customization.

The labeling machine has high labeling accuracy and good quality, Applicable to the requirements of high precision, high output products, and it is difficult to see the error with the naked eye.

Working principle:

1.Click on star on the touch screen.

2.The product placed on the separate card institution and the separate card institution moves the products forward to conveyor belt one by one then conveyor belt will move the products forward.

3.When the sensor detects that the products has reached target location, the machine will send out the label and the roller attaches the label to the product, a labeling process is completed.

Label specification:

①Applicable labels: sticker label, film, electronic supervision code, bar code.

②Applicable products: Products that are required to be labeled on flat, arc-shaped,round, concave, convex or other surfaces.

③Application industry: Widely used in cosmetics, food, toys, chemical, electronics, medicine and other industries.

④Application examples: shampoo flat bottle labeling, packaging box labeling, bottle cap, plastic shell labeling, etc.

label production requirements:

1. The gap between the label and the label is 2-3mm;

2. The distance between the label and the edge of the bottom paper is 2mm;

3. The bottom paper of the label is made of glassine, which has good toughness and prevents it from breaking (to avoid cutting the bottom paper);

4. The inner diameter of the core is 76mm, and the outer diameter is less than 280mm, arranged in a single row.

The above label production needs to be combined with your product. For specific requirements, please refer to the results of communication with our engineers!

Main Structure:

| No. | Structure | Function |

| 1 | Conveyor | Transmit product |

| 2 | Labeling Head | Core of the labeler, includes label-winding and driving structure |

| 3 | Touch Screen | Operation and setting parameters |

| 4 | Collection Plate | Collect the labeled products |

| 5 | Strengthening Sponge Roller | Press labeled product to strengthen labeling |

| 6 | Main Switch | Open the machine |

| 7 | Emergency Stop | Stop the machine if it runs wrong |

| 8 | Electric Box | Place electronic configurations |

| 9 | Pagination Device | Separate a stack of pouches/cards/...and feed to the conveyor one by one. |

Technical parameters:

| Parameter | Date |

| Label Specification | Adhesive sticker,transparent or opaque |

| Labeling Tolerance | ±0.5mm |

| Capacity(pcs/min) | 40~120 |

| Suit bottle size(mm) | L:40~400 W:20~200 H:0.2~150;Can be customized |

| Suit label size(mm) | L:15-100;W(H):15-130 |

| Machine Size(L*W*H) | 2080*695*1390(mm) |

| Pack Size(L*W*H) | 2130*730*1450(mm) |

| Voltage | 220V/50(60)HZ;Can be customized |

| Power | 820W |

| N.W(KG) | 200.0kg |

| G.W(KG) | 365.0kg |

| Label Roll | ID:Ø76mm; OD:≤260mm |

Features:

1 ) Control System: Japan Panasonic control system , with high stability and extremely low failure rate.

2 ) Operation System: Touch screen , directly visual interface easy operation.Chinese and English available . Easily to adjust all electrical parameters and have counting function , which is helpful for production management.

3) Detection System: German LEUZE/Italian Datalogic label sensor and Japan Panasonic product sensor , which are sensitive to label and product , thus ensure high accuracy and stable labeling performance . Greatly saves labor .

4) Alarm Function : The machine will give an alarm when problem occur , such as label spill , label broken , or other malfunctions .

5) Machine Material : The machine and spare parts all use material stainless steel and anodized senior aluminum alloy , with high corrosion resistance and never rust .

6) Equip with a voltage transformer to adapt to local voltage.

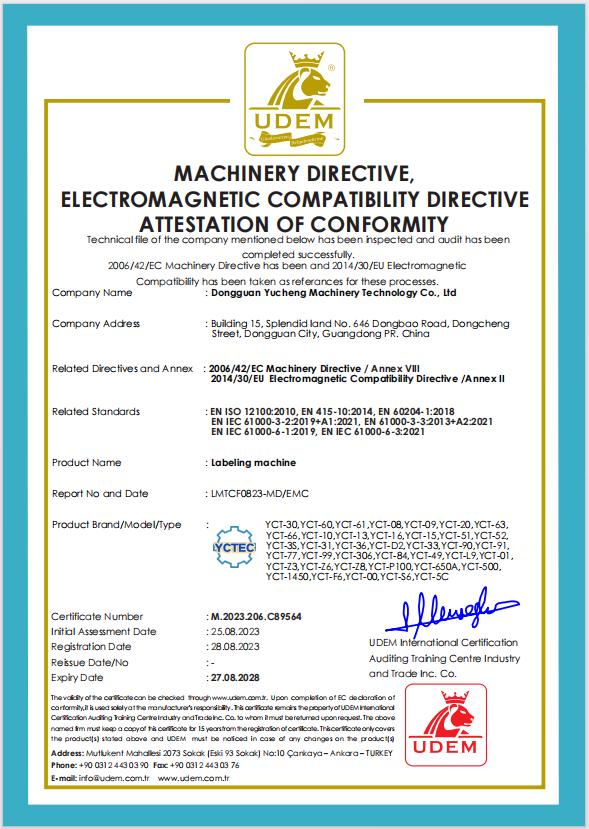

Certificate:

Video:

We have been deeply inivolved in the field of full

automatic packing equiments for more than 20 years.

We insist on making high-quality products, insisting on

making every product well, and providing customers

with better solutions, to bring safe, reliable and cost-

effective packaging machines and service to our

customers.

Yucheng Machinery

Yucheng Machinery