YCT-1000 Semi-Auto Double Side Tape Applicator

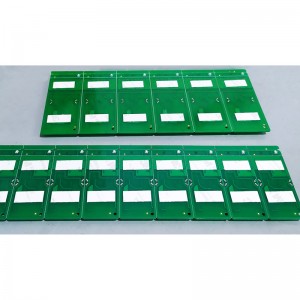

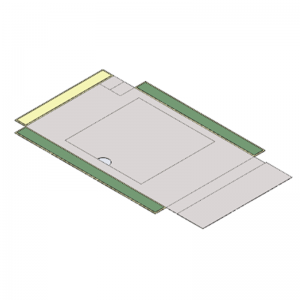

Product Application:

Machine description:

Semi-automatic Double Side Tape Applicator uses double channel design and individual controller system, this makes it possible to produce different products in one time on one machine. It is very easy and very fast to set up and change products and no need experience before training. Normally it is only need 5~10 minutes to change a new product which makes the production more efficient. The minimum thickness of the paper is 80g. This machine is the first of the kind in the world and worth you to focus on it.

KS controller use DSP high speed calculating and FPGA drive control technology. High efficiency and timely tracking design. It can make sure the high precise in high speed running. The controller is very flexible and very easy to be set. The quality, stability and reliability are more than other similar machines.

Specifications:

| Model: |

YCT-1000 |

| Material : | Over 200g/㎡ cardboard, corrugated board |

| Open blank : | min. 80 mm x 70 mm |

| max.1020 mm x 1020 mm | |

| Working width: | 1020 mm |

| Conveyor speed : | 45m/min(Depends on different boxes and tape type ) |

| Tape roll width : | 5 – 40 mm |

| Number of installable tape applicators: | 2 sets label tape applicator heads |

| Power required: | 400W(220V AC 50HZ) |

| Air Required: | Min. 6 bar |

| form advance: | Hand feeding |

| Weight: | Approx. 360KG |

| Machine Size: | 1570*1300*1200mm(L*W*H) |

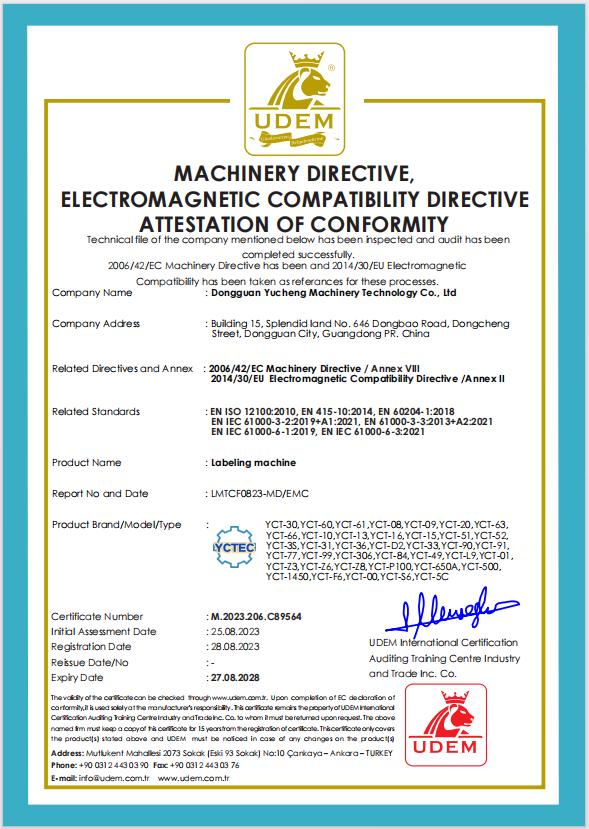

Certificate:

Video:

We have been deeply inivolved in the field of full

automatic packing equiments for more than 20 years.

We insist on making high-quality products, insisting on

making every product well, and providing customers

with better solutions, to bring safe, reliable and cost-

effective packaging machines and service to our

customers.

Yucheng Machinery

Yucheng Machinery