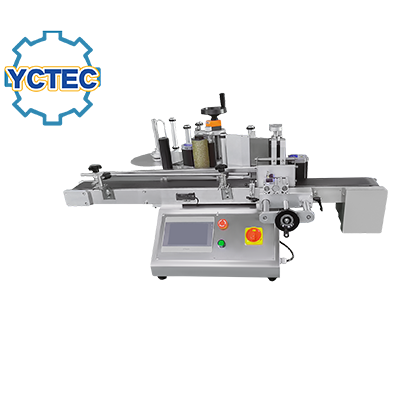

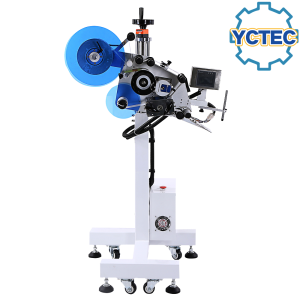

YCT-09 Table automatic positional round bottle lableing machine

Product Application:

Machine description:

The table vertical economical round bottle labeling machine works for labeling the circumference of round bottles, labeling single-label products, such as gel water round bottles, food round cans, double labeling of gel water, red wine bottles, etc. It's widely used in cosmetics, food, medicine, Disinfection water and other industries. The optional circumferential positioning detection device can realize labeling at the designated position on the circumferential surface.

Application:

Applicable labels: self-adhesive labels, self-adhesive films, electronic supervision codes, barcodes, etc.

Applicable products: round bottles with a diameter between 25mm and 90mm.

Application industry: Widely used in medicine, food, toys, daily chemicals, and other industries.

Optional functions:

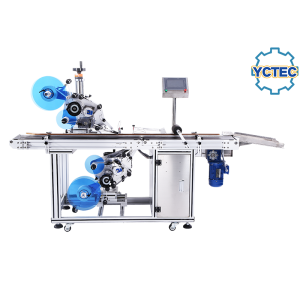

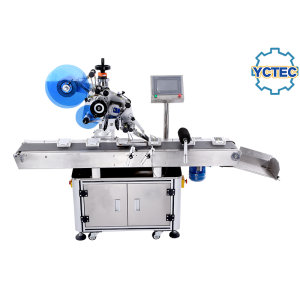

① Optional automatic rotary bottling machine.

② It can be directly connected to the production line to realize automatic bottling and improve production efficiency.

③ The optional ribbon coding machine can be added to the label head, and the production batch, production date and expiration date can be printed at the same time. Reduce packaging procedures and greatly improve production efficiency.

④ Automatic feeding function (combined with product consideration);

⑤ Automatic material collection function.

⑥ Increase labeling device;

The adjustment method is simple. It adopts the sponge labeling method, which can be labeled according to the product positioning. The labeling accuracy is high, the quality is good, and the speed is fast. It is difficult to see the error with the naked eye. It is the best choice for high-yield products.

working principle:

The PLC processes product signal and label signal,then outputs signal to the traction motor to start labeling.

Labeling Process:

Put bottles on the conveyor → The products are transmitted by the conveyor belt → The product sensor detects the product→ PLC receives the product signal and start labeling→ the conveyor belt send the labeled products to the collecting plate.

label production requirements:

1. The gap between the label and the label is 2-3mm;

2. The distance between the label and the edge of the bottom paper is 2mm;

3. The bottom paper of the label is made of glassine, which has good toughness and prevents it from breaking (to avoid cutting the bottom paper);

4. The inner diameter of the core is 76mm, and the outer diameter is less than 200mm, arranged in a single row.

The above label production needs to be combined with your product. For specific requirements, please refer to the results of communication with our engineers!

Technical parameters:

| Parameter | Date |

| Label Specification | Adhesive sticker, transparent or opaque |

| Labeling Tolerance | ±1mm |

| Capacity(pcs/min) | 15~40pcs/min |

| Suit product size(mm) | Φ20~φ90; Hight: 30-280mm |

| Suit label size(mm) | L:15-150;W(H):10-80mm |

| Machine Size(L*W*H) | 1000*650*550(mm) |

| Pack Size(L*W*H) | 1100*700*600(mm) |

| Voltage | 220V/50(60)HZ; |

| Power | 940W |

| N.W(KG) | 70.0 |

| G.W(KG) | 100 |

| Label Roll | ID:Ø76mm; OD:≤200mm |

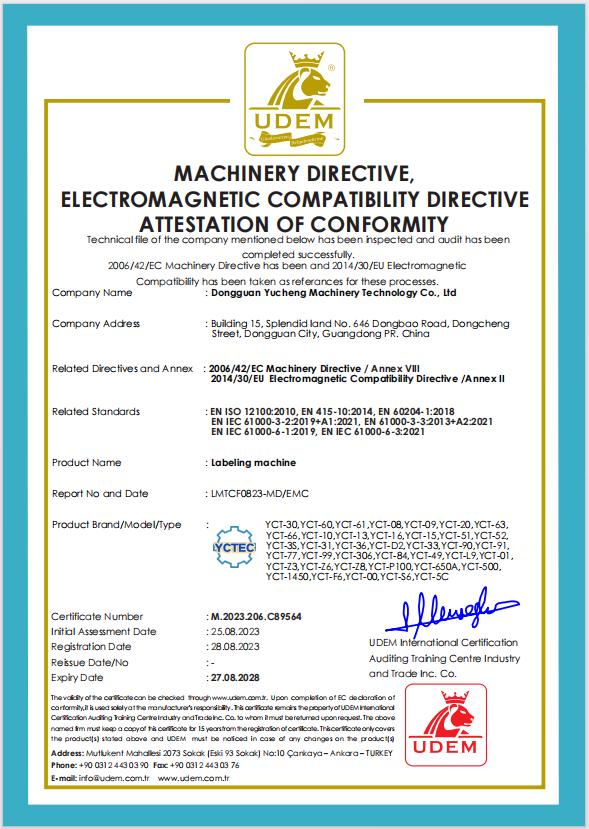

Certificate:

Video:

We have been deeply inivolved in the field of full

automatic packing equiments for more than 20 years.

We insist on making high-quality products, insisting on

making every product well, and providing customers

with better solutions, to bring safe, reliable and cost-

effective packaging machines and service to our

customers.

Yucheng Machinery

Yucheng Machinery